Revolutionizing Robotics: The Impact of Hybrid Surfaces in Algoritmus

The field of robotics is undergoing a transformative journey, fueled by advancements in artificial intelligence and automation technologies. At the heart of this evolution lies a pivotal innovation: hybrid surfaces. These cutting-edge materials are set to redefine the parameters of robotics, enabling machines to interact with their surroundings in entirely new ways.

Hybrid Surfaces: A New Era in Robotics

Hybrid surfaces combine the best qualities of different materials, resulting in enhanced functionality and adaptability. This advancement is crucial in robotics, where machines must operate in diverse environments and handle various tasks. Imagine robots that can seamlessly transition from gripping a delicate object to traversing a rugged terrain—all thanks to the sophisticated design of hybrid surfaces.

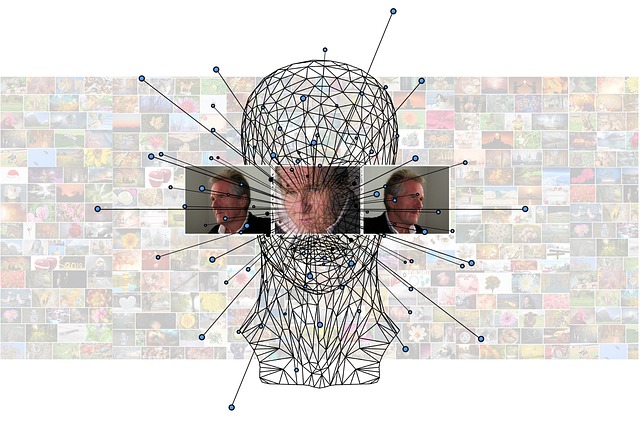

The Synergy of AI and Hybrid Surfaces

Artificial intelligence is the backbone of modern robotics. When paired with hybrid surfaces, AI systems gain a significant edge. For instance, robots equipped with tactile sensors on hybrid surfaces can better interpret the texture and weight of objects. This capability allows for more precise manipulation, making robotic arms indistinguishable from human hands in terms of dexterity and sensitivity. Consequently, industries such as healthcare and manufacturing are experiencing a surge in efficiency and accuracy.

Automatisation in Business: Transforming Operations

As businesses strive for increased efficiency and productivity, the integration of hybrid surfaces into robotic systems presents a game-changing opportunity. Automation is no longer a luxury; it’s a necessity for staying competitive. With robots that boast hybrid surfaces, companies can have machines that adapt to various tasks without the need for extensive reprogramming. This flexibility reduces downtime and maximizes output, allowing organizations to focus on innovation and growth.

Driving Change Across Sectors

The implications of hybrid surfaces in robotics extend far beyond industrial applications. In the logistics sector, for example, robots can efficiently sort and transport packages of different shapes and sizes, responding to the dynamic nature of supply chain demands. In the field of agriculture, hybrid surface robotics enable precise planting and harvesting, minimizing waste and maximizing yield. Each of these examples showcases how the integration of advanced materials into robotic systems can lead to significant advancements across multiple industries.

As we move forward, the combination of hybrid surfaces, artificial intelligence, and automation will continue to reshape the landscape of robotics. The potential is vast and exciting, as businesses and individuals harness these innovations to create a future where robots are not just tools but partners in progress.