The Intersection of Robotics and AI

As businesses continue to evolve, the integration of artificial intelligence (AI) and automation in various sectors has become nothing short of revolutionary. One of the most striking examples of this transformation is the control of robotic arms in manufacturing and other industries. The precision, efficiency, and scalability that robotic systems provide are reshaping traditional workflows, allowing companies to achieve unprecedented productivity levels.

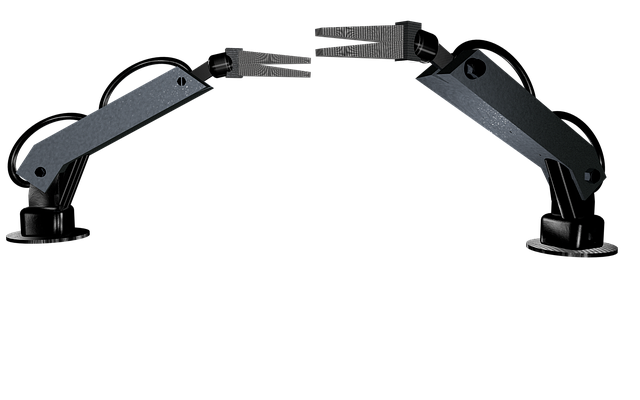

Understanding Robotic Arm Control

The control of robotic arms is at the heart of many automated processes. These sophisticated machines can perform tasks ranging from simple assembly to intricate surgical procedures, thanks to their advanced control systems powered by AI. The programming of these robots is not solely about making them move; it extends to enabling them to learn and adapt to various environments and tasks. As a result, businesses can deploy robotic arms to handle repetitive or dangerous tasks, allowing human workers to focus on areas that require critical thinking and creativity.

AI Enhancements in Robotics

Artificial intelligence enhances the control of robotic arms by providing them with the ability to learn from their experiences. With machine learning algorithms, robotic systems can process vast amounts of data from their surroundings and adjust their actions accordingly. This adaptive capability significantly boosts the efficiency of operations, reducing the likelihood of errors and downtime. Businesses that harness this power can remain agile and responsive to market demands, tailoring their workflows to meet unique challenges.

Automation in Business – The Competitive Edge

In today’s fast-paced market, automation offers a competitive edge that can be the difference between success and obsolescence. The control of robotic arms has become an integral component of automation strategies. By delegating mundane tasks to robots, businesses can streamline processes, minimize waste, and enhance overall throughput. With advancements in AI, these robotic systems can now collaborate seamlessly with human workers, creating a hybrid workforce that blends the strengths of both.

Real-life Applications

From automotive assembly lines to food production facilities, the implementation of robotic arms is widespread. For instance, at several major automobile manufacturers, robotic arms control tasks such as welding, painting, and assembling components. This not only increases the speed of production but also ensures consistency and quality in the final product. Similarly, in the food industry, robots can automate packaging and sorting processes, leading to significant improvements in efficiency and hygiene standards.

The Future of Robotic Control

The future of robotic arm control is bright, driven by ongoing advancements in AI and automation technologies. As these systems become more sophisticated, the control of robotic arms will likely become even more intuitive and responsive. Industries will continue to find innovative ways to integrate robotic arms into their operations, leading to smarter factories and enhanced production capabilities. With the power of AI, we can expect robotic arms to take on even more complex tasks, further transforming the business landscape.

As we move forward, embracing the potential of robotic arms will be crucial for businesses looking to thrive in an increasingly automated world. The combination of robotics and AI not only promises enhanced operational efficiency but also the ability to redefine how we work, collaborate, and innovate.