Understanding Basic Maintenance Algorithms in Robotics and AI Automation

In today’s fast-paced world, where robotics and artificial intelligence (AI) are revolutionizing industries, maintaining these complex systems is crucial for uninterrupted productivity. Whether it’s a manufacturing plant employing robotic arms or a business utilizing AI-driven automation, basic maintenance algorithms form the backbone of operational reliability and efficiency.

The Role of Robotics in Modern Automation

Robots have become indispensable in various sectors, ranging from assembly lines to logistics. Their ability to perform repetitive, precise tasks reduces human error and accelerates production rates. However, these machines also require routine upkeep to avoid costly downtimes. This is where maintenance algorithms step in, enabling self-diagnostics, fault detection, and predictive repairs—ensuring robots continue to operate seamlessly.

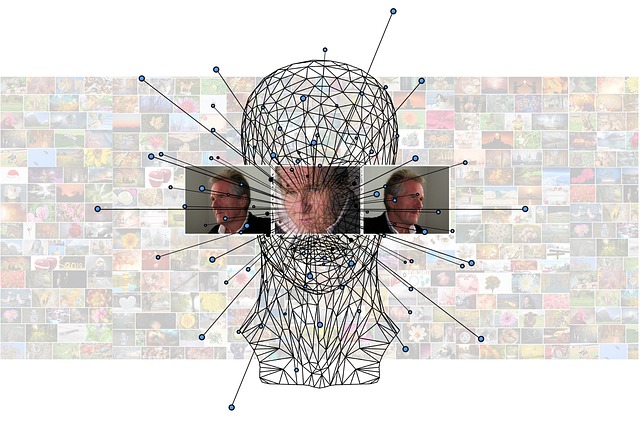

Artificial Intelligence Enhancing Maintenance

Artificial intelligence enhances maintenance strategies by learning from operational data, identifying patterns that human operators might miss. AI-powered systems leverage basic maintenance algorithms to predict potential failures before they occur. This proactive approach minimizes disruptions and extends the lifespan of robotic components.

Business Automation and Its Dependence on Reliable Systems

For businesses adopting automation, reliability is non-negotiable. Downtime means lost revenue and customer dissatisfaction. Implementing basic maintenance algorithms within automation frameworks contributes to system robustness. These algorithms help schedule timely interventions, adapt maintenance routines based on usage intensity, and balance cost-effectiveness with system health.

How Basic Maintenance Algorithms Work

At their core, these algorithms analyze telemetry data from sensors embedded in robotic systems. They monitor parameters like temperature, vibration, and operational load. When deviations occur beyond predefined thresholds, the algorithms trigger alerts or initiate corrective actions.

- Condition Monitoring: Constantly tracking system health indicators.

- Fault Detection: Identifying anomalies that suggest wear or damage.

- Predictive Maintenance: Using historical and real-time data to forecast failures.

- Automated Scheduling: Planning maintenance activities during optimal downtimes.

Why Every Modern Business Needs Basic Maintenance Algorithms

As industries evolve, integrating robotics and AI into their workflows is becoming standard practice. However, without reliable basic maintenance algorithms, even the most advanced robotic systems can falter. Companies that prioritize algorithm-driven maintenance not only optimize operational efficiency but also enhance overall business resilience.

By understanding and embracing these algorithms, industry professionals and business leaders can ensure their robotic and AI assets remain at peak performance, driving innovation and growth in a highly competitive landscape.