The landscape of business is continuously evolving, and at the forefront of this transformation is the application of cutting-edge robotics and artificial intelligence (AI). As organizations strive for greater efficiency and productivity, the concept of a zone-based approach emerges as a revolutionary strategy in the realm of automation.

The zone-based approach breaks down operations into manageable, targeted segments. This method not only enhances productivity but also allows for a more nuanced allocation of resources. In a factory setting, for instance, various zones can be created for specific tasks: assembly, quality control, packaging, and even shipping. By assigning specialized robots to these zones, businesses can optimize workflows and significantly reduce the time to market.

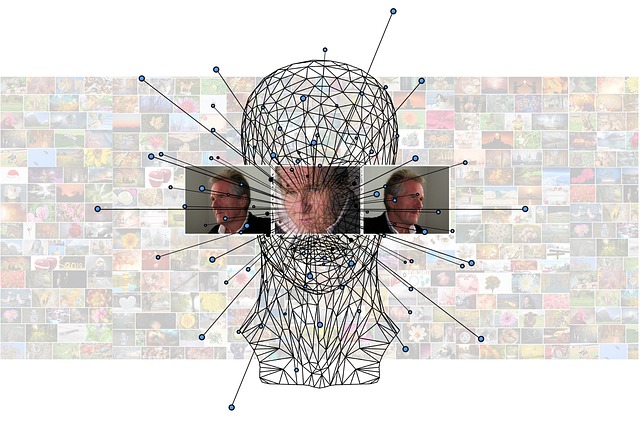

Artificial intelligence plays a critical role in this paradigm. By leveraging machine learning algorithms, AI can analyze data from each zone and provide insights that lead to improved decision-making. Imagine a scenario where a robot in a packing zone detects that the packaging material is running low. In a traditional setup, this could lead to delays as a human operator is notified, but with AI, the system can autonomously reorder supplies, keeping the workflow uninterrupted.

Furthermore, the zone-based approach creates an environment conducive to continuous improvement. Data gathered from each zone can be used to refine algorithms, leading to more intelligent robotics systems over time. This process not only saves costs but also instills a culture of innovation within the business. It fosters an atmosphere where employees and machines work in synergy, enhancing creativity and overall job satisfaction.

Implementing a zone-based approach also means businesses can easily scale their operations. As demand fluctuates, companies can quickly adjust the size and number of zones according to their needs, deploying additional robots or reallocating existing ones with minimal disruptions. This flexibility is crucial in today’s fast-paced market, where customer expectations are continuously shifting.

Moreover, the benefits extend beyond mere operational efficiency. The emotional intelligence tethered to robotics and AI becomes a significant differentiator. As employees witness the enhanced capabilities of their work environments—streamlined processes, less menial tasks, and a focus on creativity and strategy—they can develop a stronger connection with the technology that surrounds them. This emotional engagement not only boosts morale but also promotes a culture of collaboration between humans and machines.

In sectors such as healthcare, logistics, and manufacturing, the zone-based approach can have transformative effects. For instance, in healthcare, different zones could facilitate various patient care operations, from administration to diagnostics. AI-driven analytics can inform medical professionals of trends, aiding in proactive decision-making that directly benefits patient care.

The transition to a zone-based approach in robotics and AI necessitates thoughtful consideration. Businesses must invest in training their employees to adapt to this new paradigm and to understand the tech they are working alongside. This investment is crucial as understanding the synergy between human intelligence and machine efficiency will enable businesses to reach new heights.

As we continue to explore the potential of robotics and AI, the zone-based approach stands out as a beacon of innovation. It heralds a future where businesses are not just automated but are intelligent systems in their own right—driven by insightful data, empowered human teams, and agile operations. The ramifications of this approach are expansive, and it promises to redefine our concept of work in the age of automation.