In the rapidly evolving landscape of modern business, the fusion of robotics, artificial intelligence, and automation heralds a new era of efficiency. At the heart of this transformation lies a concept that is often overlooked yet immensely crucial: low-level control. This approach involves the intricate management of basic operations that can drastically enhance the overall performance and sophistication of automated systems.

When we think of robotics in the business context, we often picture large, complex machines operating in factories or high-tech warehouses. However, the beauty of low-level control is that it breathes life into even the simplest automations. For example, think about the robotic arms delicately assembling products on a production line. Each minuscule movement needs precise control to ensure efficiency and quality. Without this fine-tuning, errors could cascade, resulting in unwanted downtimes and additional costs.

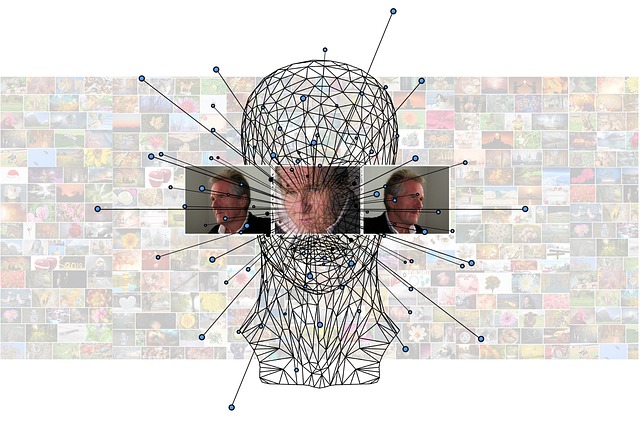

Moreover, the integration of artificial intelligence into low-level control systems allows for dynamic adjustments in real-time based on varying operational conditions. AI algorithms can analyze data points from sensors embedded in machines, determining when to accelerate or slow down processes, all while maintaining optimal output quality. This synergy between AI and low-level control empowers businesses to become agile and responsive, capable of adapting swiftly to market demands.

Embracing low-level control in automation also unlocks the potential for enhanced efficiency and cost savings. Imagine a logistics company employing AI-driven robotics for inventory management. These robots could navigate through warehouses, picking and packing items with unprecedented speed and accuracy. Each action—whether it’s moving an item or detecting an obstruction—hinges on effective low-level control. The ripple effect of this efficiency not only streamlines operations but also frees up human resources to focus on more strategic tasks.

Moreover, with the advent of machine learning and advanced algorithms, low-level control systems can evolve over time, learning from past activities and transcending simplistic automation. They can develop more complex patterns of operation that enhance the overall synergy between robotics and business strategy. Such innovation doesn’t just facilitate operations; it cultivates an environment of continuous improvement—a hallmark of successful modern enterprises.

However, the journey to implementing low-level control is not without its challenges. Businesses must navigate the nuances of integration, ensuring that both technology and human workers can operate harmoniously. This requires not only investment in cutting-edge technologies but also in workforce training and development, allowing employees to leverage these advancements in their day-to-day roles. The balance between human oversight and automated efficiencies is critical, ensuring that innovation does not outpace understanding.

As we step further into this age of business automation, the role of low-level control will become increasingly significant. It forms the indispensable backbone that supports the intricate dance between robotics and AI, allowing businesses to reap the full benefits of automation. The quest for refinement in efficiency is not just a technological imperative but a philosophical shift toward a smarter, more interconnected way of working.